What is Plastic Injection Molding?

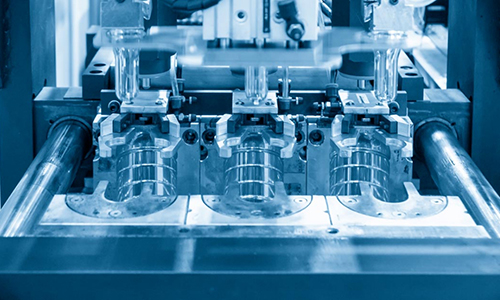

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold, or mold. Injection Molding can be performed with a host of materials mainly including and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and injected into a mold cavity, where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, molds are made by a mold-maker (or toolmaker) from metal, usually either steel or aluminum, and precision-machined to form the features of the desired part. Injection Molding is widely used for manufacturing a variety of parts

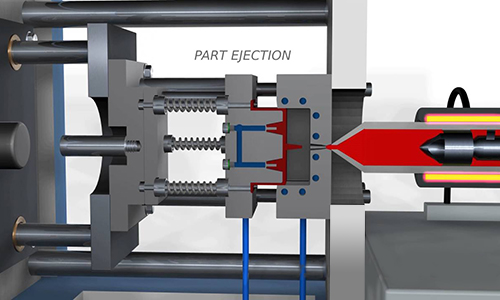

Injection Molding uses a special-purpose machine that has three parts: the injection unit, the mold, and the clamp. Parts to be injection-molded must be very carefully designed to facilitate the molding process; the material used for the part, the desired shape and features of the part, the material of the mold, and the properties of the Molding machine must all be taken into account. The versatility of injection molding is facilitated by this breadth of design considerations and possibilities.

Advantages of Injection Molding

Fast production, Design flexibility, High-output production.

Plastic injection Molding is one of the most popular plastic producing processes in the world today, for long manufacturing runs. Just look around – you’re certain to see plenty of products that were likely made via the process.

Plastic injection Molding is such a precise method that it can fabricate nearly any type of plastic part. There are certain design restrictions, but the molds that are made allow the finished product to be very precise.

Injection Molding equipment typically runs with a self-gating, automatic tool to keep operations streamlined and production ongoing, requiring minimal supervision.

With so much attention being paid to sustainability these days, it’s commonplace for product developers to choose processes that benefit the environment and minimize waste. Plastic injection Molding isn’t only an efficient, effective process, but it is also resourceful. That’s because a) only as much plastic as is necessary is used to create the part and b) excess plastic can be ground up and recycled after use.

Aside from being an accurate production process, plastic injection Molding is also a flexible one. By this, we mean that it’s simple to change the type of material that is being produced as well as the color that the product is being produced in.

The initial creation of the mold can be expensive, costing thousands or tens of thousands of dollars. But once the tool is created, you can create a large number of plastic components, actually millions

Please have a look at our injection molding process for more information on how to get started on your injection molding project. Please contact us and we will be happy to provide you with a quotation or any advice you require.