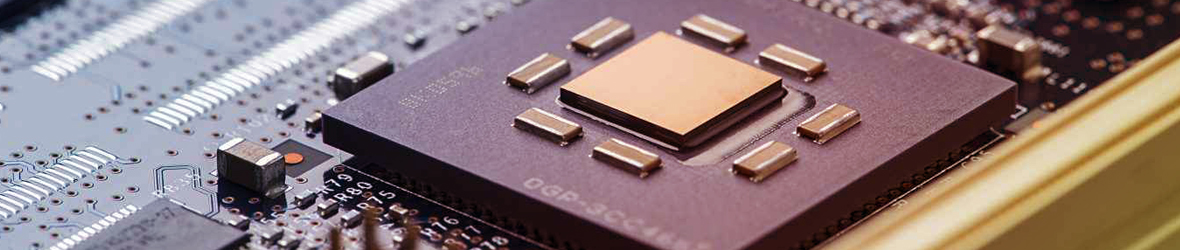

Printed Circuit Board Assembly (PCBA)

Printed circuit board assembly, or PCB assembly (PCBA), is the process of using surface mount technology (SMT) or pin through hole (PTH) to solder components like transistors, resistors, and integrated circuits onto a bare board. A completed PCBA lets you route power and signals between physical devices.

|

|

Megatone Electronics specializes in highly complex PCB assembly and advanced manufacturing systems in meeting customers’ dynamic business needs.

We offer comprehensive PCB Assembly services that help our customers fully realize their design from prototype assembly to small-to-high-volume production.

From simple single-sided assemblies to complex densely populated fine pitch and BGA surface mount assemblies, the Megatone engineering team offers specialized PCBA manufacturing solutions using our QA process control and advanced production equipment.

Megatone PCB Assembly (PCBA) Capabilities:

- Material Management and Solutions – Version and Batch Controls, Parts Procurement, Full Turnkey, Partial Turnkey, Kitted/Consigned, and Alternative Parts Recommendation

- PCB – Single-Sided, Double-Sided, Multi-layer

- PCB Shapes – Regular, Irregular, Complex, Slots, and Cut-outs

- PCB Finishes

- HASL (Hot Air Solder Level)

- ENIG (Electroless Nickel Immersion Gold)

- OSP (Organic Soldering Preservative)

- Gold Flash

- Electrolytic Gold

- Electroless Gold and Silver

- Immersion Gold, Silver, and Tin

- Stencils – Laser Cut, Stainless Steel, Nano Coating, Standard and Multi-Layer

- SMT (Surface Mount Technology)

- 008004, 01005

- BGA (Ball Grid Array)

- Micro BGA

- VFBGA (Very Thin Profile Fine Pitch BGA)

- QFN (Quad Flat No-lead)

- DFN (Dual Flat No-lead)

- QFP (Quad Flat Package)

- CCGA (Ceramic Column Grid Array)

- CSP (Chip Scale Package)

- Convection Re-flow Oven

- PTH (Pin Through Hole)

- Automated Insertion

- Manual Insertion

- Hand Soldering

- Wave Soldering

- No-clean Process

- Overmolding

- Conformal Coating

- Encapsulation (Potting)

- Electromechanical Assembly and Box Build

- BTO (Build-to-Order)

- CTO (Configure-to-Order)

- DOF (Direct Order Fulfillment

- Inspection and Testing

- Visual Inspection

- AOI (Automated Optical Inspection)

- ICT (In-Circuit Test)

- X-Ray Analysis

- Functional Testing

- Accelerated Life Testing

- Burn-in Testing

Megatone Advantages:

- We provide Design for Manufacturability (DFM) and Testability (DFT) to increase efficiency and reduce your overall cost

- We provide complete PCBA manufacturing strategies and life cycle solutions from the pre-manufacturing engineering stage, production, post-manufacturing, logistics, fulfillment to client support to make certain manufacturing success

For more information, please contact us.